The Five Tibetan Rites, a series of ancient exercises, are gaining popularity, prompting searches for a reliable 5 Tibetan Rites PDF guide.

These rites, traditionally believed to enhance vitality, are documented in various online resources, offering a pathway to improved wellness and physical conditioning.

Many seek comprehensive guides to understand and correctly perform these exercises, aiming to unlock their potential benefits for energy and overall health.

Historical Origins and Background

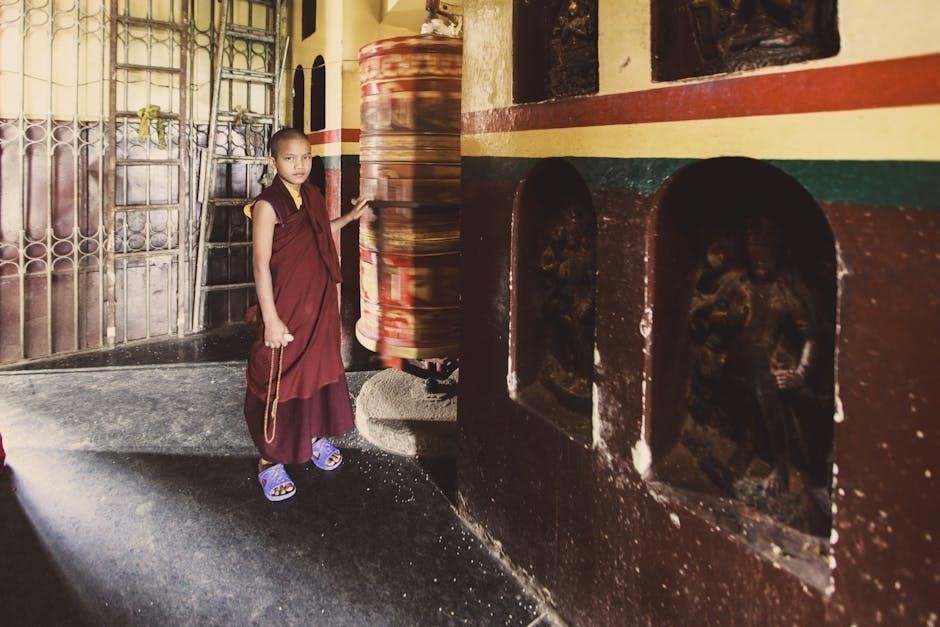

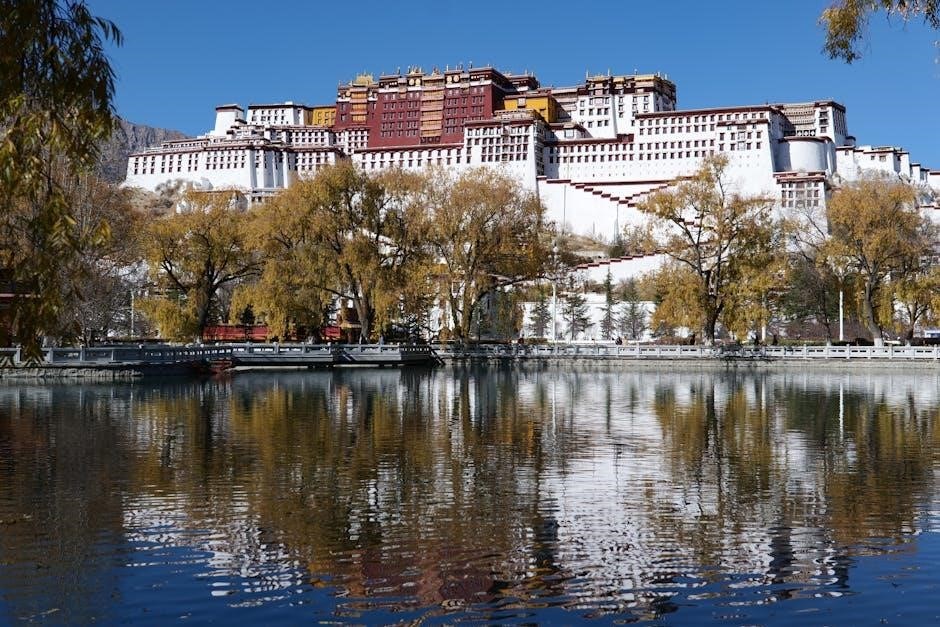

The origins of the Five Tibetan Rites are shrouded in mystery, often linked to an ancient Tibetan yoga tradition within secluded monasteries. Accounts suggest these rites were practiced by monks to maintain physical and mental well-being in the harsh Himalayan environment.

Peter Kelder, a British soldier, popularized the rites in the West during the 1930s after reportedly learning them during his time in India. He detailed the exercises in his book, “The Eye of Revelation,” sparking initial interest. However, the precise historical lineage remains debated, with some questioning the authenticity of Kelder’s account.

Despite the ambiguity, the rites have endured, gaining traction as a holistic practice; The search for a 5 Tibetan Rites PDF reflects a modern desire to connect with these ancient traditions. Many online resources attempt to trace the rites’ roots, often referencing Tibetan Buddhist practices and yogic principles, though concrete historical evidence remains elusive.

The Core Philosophy Behind the Rites

The core philosophy of the Five Tibetan Rites centers around stimulating and balancing the body’s energy centers, often referred to as chakras; The rites are believed to invigorate the endocrine system, promoting hormonal balance and overall vitality. This aligns with ancient yogic principles emphasizing the connection between physical postures, breathwork, and energetic flow.

The practice aims to increase prana, or life force energy, throughout the body, leading to enhanced physical and mental well-being. Many seeking a 5 Tibetan Rites PDF are drawn to this holistic approach, viewing the rites as more than just physical exercises.

The rites are also thought to cleanse and rejuvenate the body, removing energetic blockages and promoting a sense of inner harmony. This philosophy emphasizes self-healing and the body’s innate ability to maintain health when properly stimulated.

Detailed Breakdown of Each Rite

Detailed instructions for each of the Five Tibetan Rites are often found within a comprehensive 5 Tibetan Rites PDF, ensuring proper form and technique.

These guides break down each rite step-by-step.

Rite 1: The Twirling Rite ⏤ Technique and Form

The first rite, often detailed in a 5 Tibetan Rites PDF, involves standing straight with arms outstretched horizontally, palms facing down. Begin to spin, maintaining balance and a steady pace, typically clockwise.

Many guides emphasize keeping the feet shoulder-width apart and focusing on a fixed point initially to prevent dizziness.

As you become accustomed to the movement, gradually increase the speed, aiming for a controlled, fluid rotation.

A quality PDF will illustrate the correct arm and body positioning, highlighting the importance of maintaining a straight back and relaxed shoulders.

Beginners are advised to start with a few rotations and gradually increase the repetitions as their balance and coordination improve.

The rite is believed to stimulate energy flow and enhance balance, and a well-structured PDF will offer modifications for those with inner ear issues or dizziness.

Rite 2: The Leg Raise ‒ Proper Execution

The second rite, frequently illustrated in a comprehensive 5 Tibetan Rites PDF, begins with standing at attention, arms at your sides. Inhale deeply and raise both legs straight out in front of you, keeping them together and lifted to hip height.

Exhale as you slowly lower your legs back to the starting position. A detailed PDF guide will emphasize maintaining a straight back throughout the exercise, engaging your core for stability.

Beginners may find it helpful to support themselves by holding onto a chair or wall initially.

The PDF should also caution against arching the back, as this can strain the lower spine.

Focus on controlled movements, avoiding jerky motions.

This rite strengthens the core and legs, and a good PDF resource will suggest starting with a smaller number of repetitions and gradually increasing them as strength improves.

Rite 3: The Spinal Bend ‒ Step-by-Step Guide

The third rite, often detailed in a 5 Tibetan Rites PDF, starts with standing with feet shoulder-width apart, knees slightly bent. Inhale deeply and exhale as you bend forward from the waist, letting your arms hang loose.

Keep your back rounded, chin towards your chest, and gaze at your feet. A quality PDF will stress the importance of a relaxed neck and shoulders.

Inhale as you slowly return to the upright position, vertebra by vertebra, tightening your abdominal muscles.

A comprehensive PDF guide will advise against jerking movements, emphasizing a smooth, controlled bend.

Beginners may find it helpful to perform this rite slowly, focusing on spinal articulation.

This rite improves spinal flexibility and stimulates abdominal organs; a good PDF will recommend listening to your body and avoiding overextension.

Rite 4: The Table Top ‒ Correct Positioning

Rite four, frequently illustrated in a detailed 5 Tibetan Rites PDF, begins with sitting on the floor with your legs crossed. Place your hands flat on the floor behind you, fingers pointing towards your feet.

Now, lift your hips off the floor, creating a “table top” position with your body forming a straight line from shoulders to knees.

A reliable PDF resource will emphasize keeping your head in line with your spine, avoiding neck strain.

Engage your core muscles to maintain stability and prevent lower back arching.

Hold this position, breathing deeply and evenly, as described in most 5 Tibetan Rites PDF guides.

Beginners might start with shorter holds, gradually increasing duration as strength improves. A good PDF will also highlight the importance of proper form over extended hold times.

Rite 5: The Full Body Stretch ‒ Achieving the Pose

Rite five, often detailed in a comprehensive 5 Tibetan Rites PDF, initiates from the tabletop position established in rite four. Inhale deeply as you arch your back, dropping your head back and looking towards the ceiling.

Exhale and tuck your chin to your chest, rounding your spine upwards, like a cat stretching. A quality PDF guide will stress coordinating breath with movement.

This rhythmic arching and rounding should flow smoothly, creating a wave-like motion through the spine.

Many 5 Tibetan Rites PDF resources emphasize maintaining control throughout the movement, avoiding jerky motions.

Focus on stretching the entire body, from your head to your tailbone.

Beginners can modify this rite by reducing the range of motion, as suggested in many beginner-friendly PDF guides.

Benefits of Practicing the Five Tibetan Rites

5 Tibetan Rites PDF resources highlight benefits like increased energy, improved flexibility, and enhanced mental clarity, promoting a youthful vitality and well-being.

Increased Energy Levels and Vitality

5 Tibetan Rites PDF guides consistently emphasize a significant boost in energy levels as a primary benefit. Practitioners often report feeling more invigorated and less fatigued after incorporating these rites into their routine.

The exercises are believed to stimulate the flow of prana, or life force energy, throughout the body, combating sluggishness and promoting a sense of vitality. This increased energy isn’t simply a temporary surge; many users describe a sustained improvement in their overall energy reserves.

Resources detail how the rites work to balance the body’s energy centers, leading to a more harmonious and efficient energy distribution. This can translate into greater stamina, reduced reliance on stimulants, and an enhanced capacity to handle daily challenges with vigor. The Fountain of Youth claim stems from this revitalizing effect.

Improved Physical Strength and Flexibility

A comprehensive 5 Tibetan Rites PDF will highlight the rites’ impact on both physical strength and flexibility. These exercises aren’t about building bulk; instead, they focus on developing functional strength – the kind used in everyday movements.

The rites engage multiple muscle groups simultaneously, strengthening the core, legs, arms, and back. The twisting and stretching motions improve joint mobility and range of motion, leading to increased flexibility over time.

Many guides emphasize the rites as a full-body workout, capable of improving balance and posture. Regular practice can alleviate stiffness, reduce muscle tension, and enhance overall physical conditioning. The exercises are designed to work with the body, promoting natural movement patterns and preventing injury.

Enhanced Mental Clarity and Focus

A well-structured 5 Tibetan Rites PDF often details the profound mental benefits alongside the physical ones. The rhythmic and mindful nature of the rites promotes a sense of calm and centeredness, fostering mental clarity.

The focused breathing techniques integral to each rite encourage present moment awareness, reducing mental chatter and anxiety. This practice can improve concentration and cognitive function, leading to enhanced focus throughout the day.

Many practitioners report a heightened sense of mental alertness and improved memory after consistent practice. The rites are believed to stimulate energy flow, not just within the body, but also within the nervous system, contributing to a clearer, more focused mind.

Potential for Weight Management

Numerous resources, including a detailed 5 Tibetan Rites PDF, highlight the potential for weight management as a secondary benefit of consistent practice. While not a dedicated weight-loss program, the rites contribute to increased metabolic rate and energy expenditure.

The full-body nature of the exercises engages multiple muscle groups, promoting calorie burn and building lean muscle mass. This, in turn, supports a healthier body composition over time.

Furthermore, the increased energy levels and improved vitality often associated with the rites can encourage a more active lifestyle, further aiding in weight management efforts. It’s important to note that a healthy diet remains crucial for optimal results, complementing the benefits derived from the rites.

Safety Considerations and Precautions

5 Tibetan Rites PDF guides often emphasize caution; individuals with pre-existing conditions should consult a healthcare professional before starting this practice.

Modifications are crucial!

Contraindications and Who Should Avoid the Rites

5 Tibetan Rites PDF resources frequently highlight specific contraindications, emphasizing that these exercises aren’t suitable for everyone. Individuals with certain health conditions should exercise extreme caution or avoid the rites altogether.

Those with spinal issues, including herniated discs or severe scoliosis, should refrain from performing these exercises without explicit medical clearance. Similarly, people with uncontrolled high blood pressure, heart conditions, or recent surgeries need to consult their doctor first. Pregnant women are generally advised to avoid the rites, particularly the more strenuous movements.

Individuals experiencing acute illness, inflammation, or recovering from injuries should also abstain. Furthermore, anyone prone to dizziness or balance issues should proceed with caution and potentially modify the exercises. A comprehensive 5 Tibetan Rites PDF will often include a disclaimer stressing the importance of listening to your body and stopping if you experience any pain or discomfort.

Proper Warm-up and Cool-down Procedures

A thorough 5 Tibetan Rites PDF guide will emphasize the critical importance of both warming up and cooling down. Skipping these steps can significantly increase the risk of injury and diminish the benefits of the practice.

Before beginning the rites, a gentle warm-up is essential. This should include light cardio, such as marching in place or arm circles, for 5-10 minutes, followed by dynamic stretching focusing on the spine, legs, and shoulders. Simple spinal rotations and leg swings are beneficial.

After completing the rites, a cool-down period is equally vital. This involves slow, static stretches held for 20-30 seconds each, targeting the same muscle groups used during the exercises. Deep breathing exercises can also help to calm the nervous system and promote relaxation. A well-structured 5 Tibetan Rites PDF will provide specific warm-up and cool-down routines.

Modifications for Beginners and Individuals with Limitations

A comprehensive 5 Tibetan Rites PDF should offer modifications for those new to the practice or with physical limitations. Beginners should start with fewer repetitions – perhaps just one or three of each rite – gradually increasing as strength and flexibility improve.

Individuals with back pain can modify the spinal bend by reducing the range of motion or performing it seated. Those with knee issues may need to lessen the depth of the leg raise or perform it with support. The twirling rite can be done at a slower pace or with smaller circles.

Listening to your body is paramount. A good 5 Tibetan Rites PDF will emphasize prioritizing proper form over the number of repetitions and encourage seeking guidance from a qualified instructor if needed.

Finding a Reliable “5 Tibetan Rites PDF” Resource

Locating a trustworthy 5 Tibetan Rites PDF requires careful evaluation of online sources, ensuring accuracy and safety for practice.

Prioritize guides offering detailed instructions and clear illustrations to maximize benefits and minimize potential risks.

Evaluating the Credibility of Online Sources

When seeking a 5 Tibetan Rites PDF, discerning credible sources is paramount. The internet hosts a vast array of information, but quality varies significantly. Look for resources authored by experienced yoga practitioners or individuals with a demonstrable understanding of the rites’ historical context and proper execution.

Check for author qualifications – are they certified yoga instructors or have they studied with recognized teachers of Tibetan traditions? Beware of websites making exaggerated claims about rapid transformations or miraculous cures; legitimate resources focus on gradual improvements in energy, flexibility, and mental clarity.

Assess the website’s overall professionalism. Does it have a clear “About Us” section? Are there contact details provided? A reputable source will be transparent about its origins and expertise. Scrutinize the PDF itself for clarity, accuracy, and a logical progression of instructions. Avoid PDFs riddled with grammatical errors or lacking detailed explanations of each rite.

Cross-reference information with multiple sources to verify consistency. If a PDF deviates significantly from established teachings, exercise caution. Finally, consider the website’s reputation – are there user reviews or testimonials available? While not always definitive, they can offer valuable insights.

What to Look for in a Comprehensive PDF Guide

A truly comprehensive 5 Tibetan Rites PDF should extend beyond simply listing the exercises. It must provide detailed, step-by-step instructions for each rite, accompanied by clear illustrations or photographs demonstrating correct form. Look for explanations of the breathing techniques integral to maximizing the benefits of each movement.

The guide should address common mistakes and offer modifications for beginners or individuals with physical limitations. A good PDF will also outline proper warm-up and cool-down routines to prepare the body and prevent injury. Information on the historical origins and philosophical underpinnings of the rites adds valuable context.

Furthermore, a quality guide will discuss potential benefits – increased energy, improved flexibility, enhanced mental clarity – while maintaining a realistic and balanced perspective. It should also include safety considerations and contraindications, advising who might need to avoid or modify the practice. A well-structured PDF will be easy to navigate and logically organized, making it a valuable resource for your practice.

Integrating the Rites into Your Daily Routine

Consistent practice, guided by a 5 Tibetan Rites PDF, is key; start slowly, gradually increasing repetitions, and combine with other wellness habits.

Recommended Frequency and Duration

Establishing a consistent routine is paramount when incorporating the Five Tibetan Rites into your life, and a well-structured 5 Tibetan Rites PDF can be invaluable in guiding this process. Beginners should ideally start with just one to three repetitions of each rite, gradually increasing the number as their strength and stamina improve.

A common recommendation is to perform the rites daily, preferably in the morning on an empty stomach, to maximize energy levels throughout the day. However, listening to your body is crucial; rest days are important, especially when first starting.

Over time, practitioners often work towards completing 21 repetitions of each rite. The duration of each rite itself is relatively short, but the cumulative effect of the entire sequence can be quite invigorating. Consistency, rather than intensity, is the most important factor for realizing the long-term benefits outlined in many 5 Tibetan Rites PDF guides.

Combining the Rites with Other Wellness Practices

To amplify the benefits detailed in a comprehensive 5 Tibetan Rites PDF, consider integrating these ancient exercises with other holistic wellness practices. Mindfulness techniques, such as meditation or deep breathing exercises, can enhance the mental clarity and focus often associated with the rites.

Pairing the rites with a healthy diet rich in whole foods provides optimal nourishment for the body, supporting increased energy levels and vitality. Yoga and stretching routines complement the rites by further improving flexibility and range of motion.

Furthermore, incorporating regular cardiovascular exercise can boost overall physical fitness. Many 5 Tibetan Rites PDF resources suggest that combining these practices creates a synergistic effect, promoting a balanced and harmonious approach to well-being, fostering both physical and mental resilience.